- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Automotive

- Solutions

- Explosion-Proof Lighting

- Explosion-Proof Lighting

- Robot Collaboration

- Robot Collaboration

- Dual-Action Interlocking

- Dual-Action Interlocking

- Smart Safety Gates

- Smart Safety Gates

- Large Inductors

- Large Inductors

- Small Equipment Safety

- Small Equipment Safety

- Solutions

- Automotive

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Robotics

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotics

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

-

Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Emergency Stop

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Special Vehicles

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Control Panel

- Solutions

- Solutions

- Control Panel

Retrieving Area Safety | APAC

How can accidents be prevented when safety guards cannot be installed at retrieving areas?

Lack of accuracy and safety with general-purpose sensors

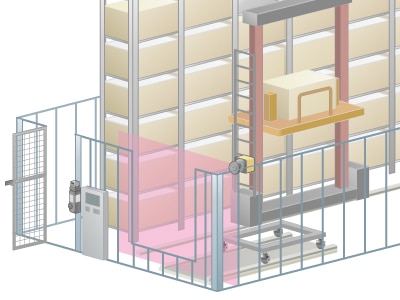

Automated storage is surrounded by safety guards to prevent accidents from occurring, that can be caused by people who enter the hazardous area unintentionally. However, since the safety guard is lower at the retrieval area of products, people might enter and they might touch the stacker lane. In order to prevent accidents, general-purpose sensors are installed to detect humans who are about to enter the hazardous zone, and to stop the equipment.

However, detection is not enough sometimes, when people are intentionally allowed to go in. Some applications use safety mat switches to detect human intrusion with weight, however, detection accuracy is not so high and switches may fail when strong pressure is applied, such as heavy objects, which leaves concerns about safety and convenience.

A safety laser scanner solve two issues

The method that IDEC proposes in order to prevent accidents at areas around product retrieval areas is the SE2L series safety laser scanner. This sensor can cover maximum of 5m and the range of 270 degrees. In the area within 1.8m, it can detect objects with high accuracy of the minimum width of ø30mm. With this capability, whether it is an arm or a leg that enters the hazardous zone, it can be detected without failure stopping the equipment quickly. Unlike light curtains, it can be operated as a single unit. It is small in size and light weight that it can be easily installed on top of the safety guard around the retrieval area. It is possible to set the detection range depending on the location and situation.

For example, the detection range can be set to ignore the movements of carts that are automatically-run, and to detect other movements only. Of course, because it is installed at locations where people cannot touch, there are no worries for failures we have with safety mat switches. With sensors like this, automated storage can be designed more safely.

Monitor 2 areas with one safety laser scanner

The SE2L series safety laser scanner can monitor intrusions to two hazardous zones separately and stop equipment with a dual protection function. In other words, if retrieval areas of two automated storage systems are close to one another, one unit can cover both. Cost to operate two light curtains can now be reduced. If you have any issues with design of systems around automated storage, please consult with IDEC. We have effective solutions with additional benefits.