• Fix the conductors in the enclosure as necessary

• For a nonmetallic duct, use a flame retardant insulation material.

• The wiring of the electrical equipment mounted in the enclosure should be modified from the front. If a control device is connected on the back side of the enclosure, a door or outward opening panel shall be provided.

• A flexible conductor shall be used for connections to the parts mounted on a door or moving part.

• The conductors and cables that are not accommodated in ducts shall be appropriately fixed .

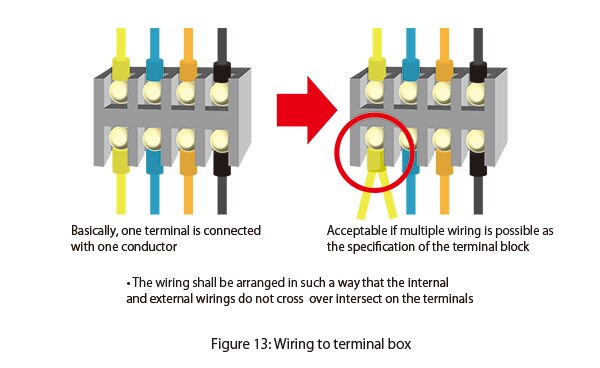

• The wiring for control circuit to the outside of the enclosure shall be connected via a terminal box or a plug and socket combinations .

Colour coding

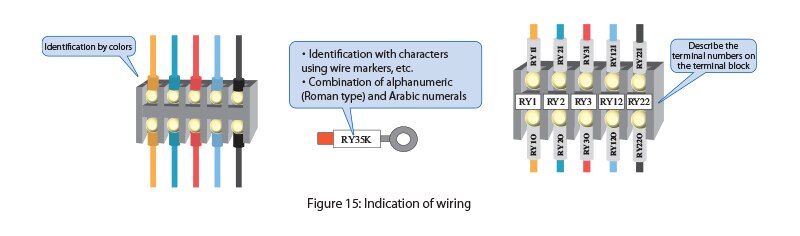

The conductors shall be identifiable using indications or colors.

Colors that can be used: black, brown, red, orange, yellow, green, blue (including light blue), purple, gray, white, pink, and turquoise (blue green)

Table 6: Wiring colors (recommended)| For power supply | Colour-coding(IEC 60204-1:2005) |

| AC power circuit | Black (light blue is recommended for neutral conductor) |

DC power circuits | Black |

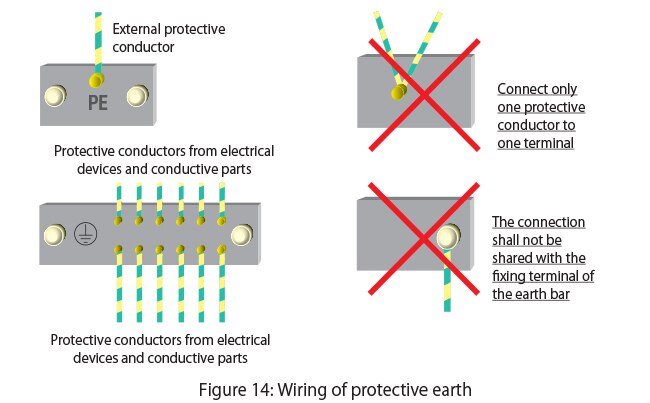

| Protective conductor | Combination of green and yellow  |

| AC control circuits | Red |

| DC control circuits | Blue |

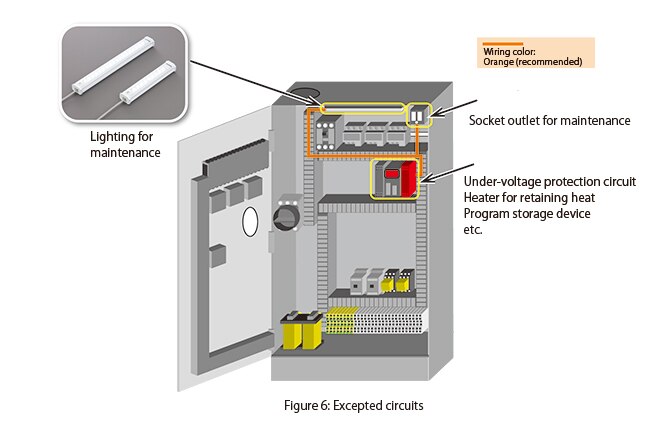

| Excepted circuits | Orange |

Protective conductor: a combination of green and yellow (one color covers 30% or more and 70% or less) shall not be used for the wiring other than protective conductors/protective bonding conductors.

Cases where the wiring colors above may not be observed

• Individual devices that are purchased with their internal wiring completed. When no insulator with the specified color is available.

• When a multi core cable is used with colors other than the combination of “yellow and green”.

Warning signs, nameplates, marking and identification plates shall be of sufficient durability to withstand the physical environment involved. (16.1)

For enclosures with built-in electrical equipment at risk of causing electric shock, the graphic symbol on the right shall be displayed.

For enclosures with built-in electrical equipment at risk of causing electric shock, the graphic symbol on the right shall be displayed.

It is necessary to consider the risk of a hot surface due to the components of electrical equipment that generate heat. The temperature of parts which a person could come in contact shall not exceed the limiting value required in ISO 13732-1.

It is necessary to consider the risk of a hot surface due to the components of electrical equipment that generate heat. The temperature of parts which a person could come in contact shall not exceed the limiting value required in ISO 13732-1.

For the parts where the limiting value may be exceeded, protective measures against unintended contact shall be provided or the graphic symbol on the right shall be displayed.

13. Technical documentation

Information required for nameplates used in the facility

• name or trade mark of supplier

• certification mark or other marking that can be required by local or regional legislation, when required. .

• type designation or model, where applicable

• serial number where applicable

• main document number (see IEC 62023) where applicable

• rated voltage, number of phases and frequency (if AC), and full-load current for each incoming supply

The following shall be supplied as technical documentation

a) where more than one document is provided, a main document for the electrical equipment as a whole, listing the complementary documents associated with the electrical equipment.

b) Identification of electrical equipment (refer to 16.4)

c) Including the following, information on installation and mounting

• Description of installation and mounting of electrical equipment and connection to an electrical supply (if applicable, other electrical supplies)

• Short circuit current rating of electrical equipment of each electrical supply

• Voltage rating, number of phases and frequency (for AC), type of earthed system (TT, TN, IT), and full load current of each input electrical supply

• Additional conditions of electrical supply related for each input electrical supply (for example, maximum supply impedance, leakage current)

• Space required for removal or service of electrical equipment

• Requirements for installation, if it is necessary to ensure that arrangement for cooling is not impaired

• Environmental restrictions (for example, lighting, vibration, EMC environment, and airborne contaminants), as necessary

• Functional restrictions (for example, start peak current and allowable voltage drop), as necessary

• Precautionary measures related to electromagnetic compatibility required for installation of electrical equipment

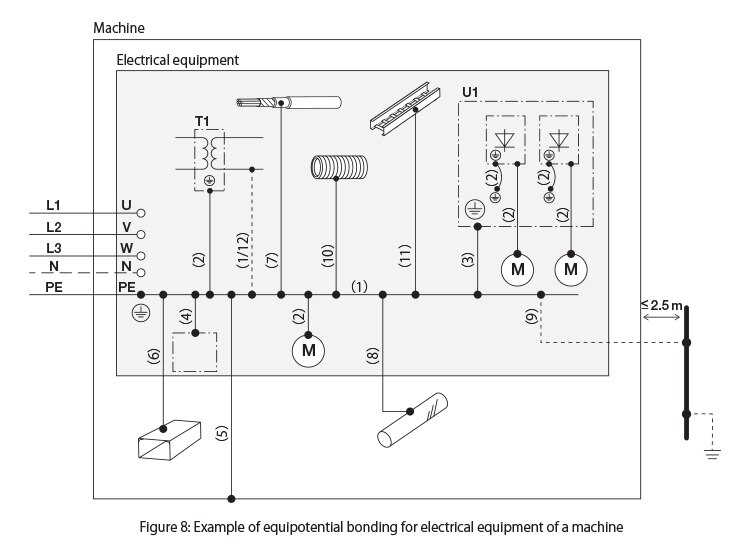

d) an instruction for the connection of simultaneously accessible extraneous-conductiveparts in the vicinity of the machine (for example, within 2,5 metres) such as the following to the protective bonding circuit

• Metallic pipe

• Fence

• Ladder

• Handrail

e) Information on the functions and operations including the following (as necessary)

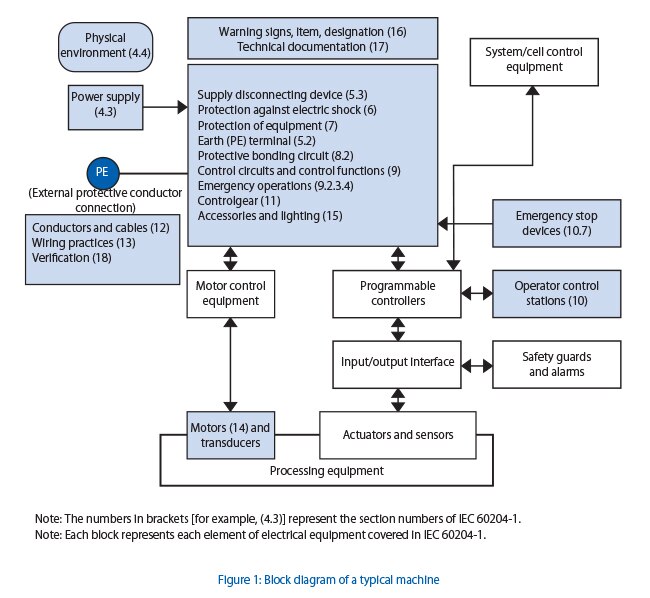

Overview of the structure of electrical equipment (for example by structure diagram or overview diagram))

• Procedure of programming or configuration required for intended usage

• Procedure of restart after an unexpected stop

• Operation sequence

f) Information on maintenance of electrical equipment including the following (as necessary)

• Frequency and method of function testing

• Instruction on the procedure to safely perform maintenance, and the procedure to interrupt the safety functions and/or protective measures (refer to 9.3.6)

• Guide for frequencies and methods of adjustment, repair and preventive maintenance

• Details of interconnection of electrical devices for replacement (for example, with a circuit diagram and/or connection table)

• Information on required special devices or tools

• Information on spare parts

• Information on possible residual risks, description of necessity of special trainings, and specifications of personal protective equipment if necessary

• Explanation of restriction limiting use of the keys or tools to only electricians and electrical workers, when applicable

• Settings (dip switches, programmable parameter values, etc.)