We use cookies to ensure that we give you the best experience on our website. If you continue, you agree with our policy statement.

- Home

- What is a safety light curtain?

- IDEC safety concept

- IDEC safety concept

- IDEC collaborativesafety / Safety 2.0

- IDEC collaborativesafety / Safety 2.0

- Safety-related laws and standards

- Safety-related laws and standards

- Safety Applications

- Safety Applications

- Safety Components: The Basics

- Safety Components: The Basics

- Introducing SISTEMA

- Introducing SISTEMA

- Safety Solution

- IDEC safety concept

- IDEC safety concept

- IDEC collaborativesafety / Safety 2.0

- IDEC collaborativesafety / Safety 2.0

- Safety-related laws and standards

- Safety-related laws and standards

- Safety Applications

- Safety Applications

- Safety Components: The Basics

- Safety Components: The Basics

- Introducing SISTEMA

- Introducing SISTEMA

-

Safety Solution

- IDEC safety concept

- IDEC safety concept

- IDEC collaborativesafety / Safety 2.0

- IDEC collaborativesafety / Safety 2.0

- Safety-related laws and standards

- Safety-related laws and standards

- Safety Applications

- Safety Applications

- Safety Components: The Basics

- Safety Components: The Basics

- Introducing SISTEMA

- Introducing SISTEMA

- Keep Clean

- Keep Clean

- Reducing Costs

- Compact components

- Compact components

- LED lighting

- LED lighting

- PLCs

- PLCs

- PLC/HMI programming suite

- PLC/HMI programming suite

- Extended-life components

- Extended-life components

- Reducing Costs

- Reducing Carbon Footprint

- PID controls/ thermal engineering

- PID controls/ thermal engineering

- Efficient power supply

- Efficient power supply

- LED lighting

- LED lighting

- 12 VDC PLCs

- 12 VDC PLCs

- Reducing Carbon Footprint

- Minimize Downtime

- Long-lasting Durable Devices

- Long-lasting Durable Devices

- Remote Monitoring and Control

- Remote Monitoring and Control

- Preventive/Predictive Maintenance

- Preventive/Predictive Maintenance

- Easy Replacements

- Easy Replacements

- Avoid Downtime Caused by Accidents

- Avoid Downtime Caused by Accidents

- Minimize Downtime

- Optimize IIoT Practices

- Remote monitoring

- Remote monitoring

- Traceable systems

- Traceable systems

- Production line safety

- Production line safety

- Smart inspection

- Smart inspection

- Optimize IIoT Practices

- Explosion Protection

- Remote Monitoring

- Remote Monitoring

- Machine Safety

- Machine Safety

- Reducing Maintenance

- Reducing Maintenance

- Traceability

- Traceability

- Expertise Support

- Expertise Support

- Explosion Protection

- Manpower Shortage

- Applying Robots

- Applying Robots

- Remote Monitoring and Control

- Remote Monitoring and Control

- Preventative Maintenance

- Preventative Maintenance

- Predictive Maintenance

- Predictive Maintenance

- Automation

- Automation

- Manpower Shortage

What is a safety light curtain? | APAC

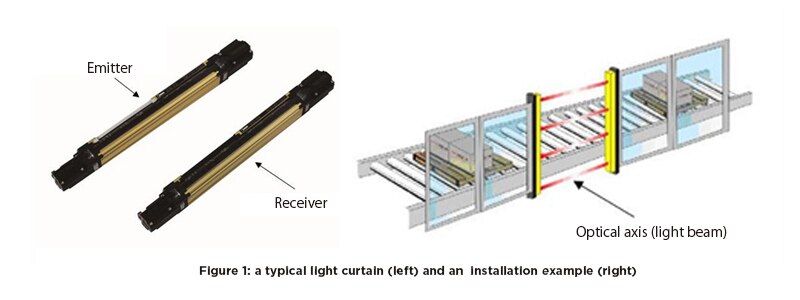

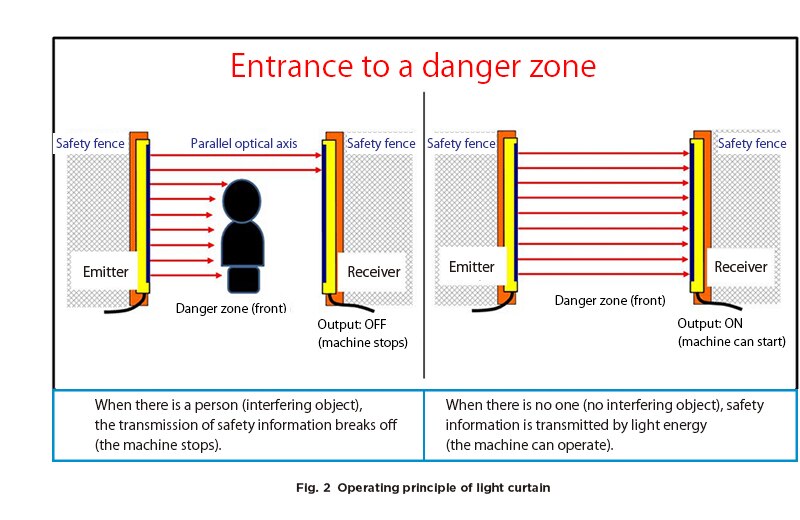

Principles of Operation

The light curtain uses a combination of an emitter and a receiver.It is set up so that multiple parallel beams emitted from the emitter are accurately received by the receiver (Figure 2). If there is no object blocking the beam between the emitter and receiver (no person is passing through), the machine is considered to be in a safe state because all light beams are reaching the receiver, and the output of the receiver is turned on to allow the machine to operate.

On the other hand, if any or all of the light beams are blocked by a human hand or body, the machine determines the situation to be hazardous and turns off the output of the receiver to stop the machine.

Application examples of Light Curtain

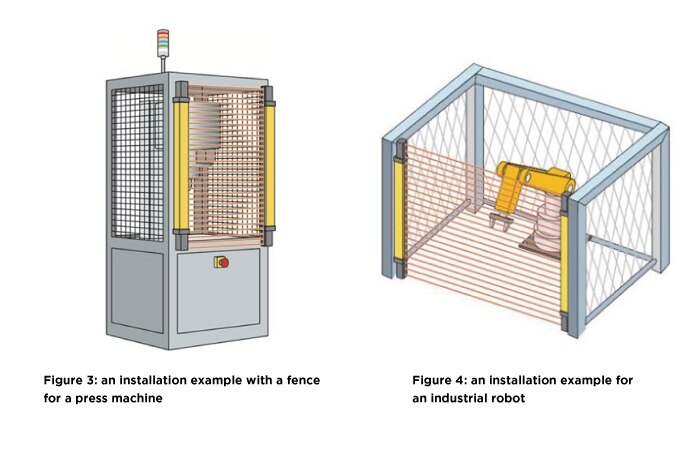

Here are some specific application examples of specific uses of light curtains.Figure 3 shows an example of installation for a press machine. A light curtain is used to detect fingers, hands, arms, or other body parts when an operator loads or unloads workpieces in a press machine with a short cycle time.

Figure 4 also shows an example of installation for an industrial robot system. Light curtains can be installed in the opening of the safety guard of an industrial robot system and used as part of the safety guard.

Use of a light curtain enables efficient setup of the workpiece from the opening of the safety guard because the door does not need to be opened and closed.

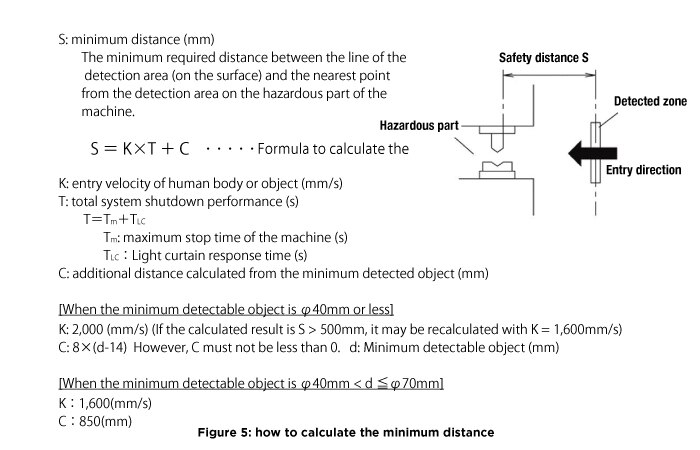

Determining Light Curtain Location—Providing the Minimum Distance

Because the light curtain is not a safety guard or a protective door that blocks entry of a person or object, a distance (S: minimum distance) must be provided to prevent a person or an object from coming into contact with the hazard source that is operating based on the time (T: overall system shutdown stopping performance) from detection of the person or object blocking the light beam until the (moving part of the) machine is brought to a stop. Determine the installation location of the light curtain based on this minimum distance (S).To do this, we must first use a light curtain with an appropriate optical axis pitch based on the size of the object that blocks the light beam.

Then, the minimum distance (S) is calculated using a predetermined formula (Figure 5).

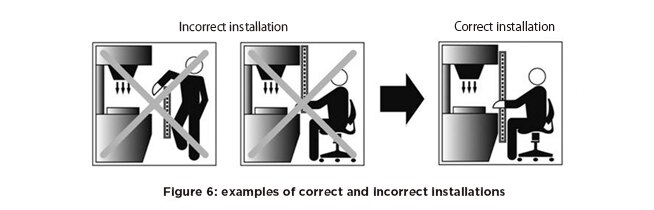

It must be installed so that no person or object can bypass the detection zone of the light curtain and enter the hazardous zone. The length for the light curtain must also be selected so that the light curtain is always situated in a location where a person or object must always pass through the detection zone of the light curtain before entering the hazardous zone (Figure 6).

Light curtains come in a variety of sizes, from about 300 mm to nearly 2,000 mm in length, and so choose the appropriate one for your installation location.

Cautions for Usage and Installation

As mentioned earlier, light curtains are devices that ensure safety without the use of safety guard or protective doors, and so several important points about their usage and installation must be followed. Some cautions are due to the light curtains being optical electronic devices.

● Chips, cutting oil, radiation, and noise from the machine cannot be blocked. Light curtains cannot be used if such items must be blocked. A combination of a protective door and an interlocking device (interlock switch) must be used.

● In areas with lots of steam or dust, light rays may be obstructed, or the lens of the emitter or receiver may become dirty, which could result in detection errors. The lenses may also need to be cleaned periodically. Check the installation environment carefully.

● External light, such as sunlight or strobe lights, can cause detection errors for the light curtain. Install the receiver so that the light receiving surface of the receiver is not directly exposed to external light.

● If there is a reflective wall or other object nearby, the receiver will receive the reflected light even if the light is blocked by a person or object, which could result in detection errors. Check before actual usage that no detection errors occur.