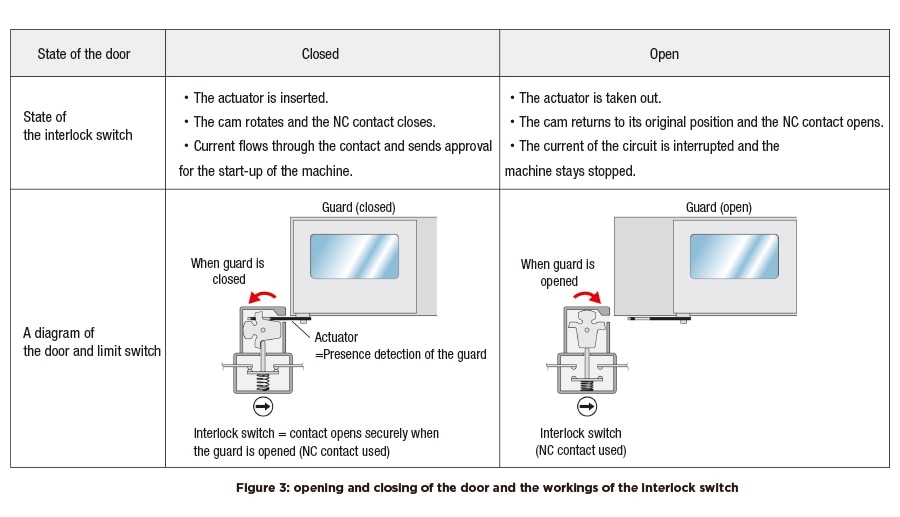

The figure on the left side of Figure 3 shows the state of the interlock switch when the door is closed, and the figure on the right side shows the state of the interlock switch when the door is open.

As shown in the figure on the left side, when the door is closed, the actuator mounted to the door turns the internal cam, and the NC contact turns on by spring force, causing current to flow in the circuit. In this state, the control system determines that the door is closed and the machine is ready for operation.

On the other hand, when the door is opened as shown in the figure on the right side, the actuator rotates the internal cam, and the NC contact is pushed down by the cam to turn off, thus cutting off the current in the circuit. In this state, the control system determines that the door is open and puts the machine into a stop state. Because this stop state is maintained, the machine will not start even if the start switch is used.

The following is a description of the structural features of the interlock switch.

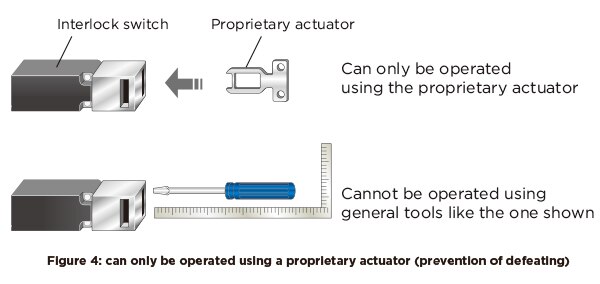

Protection against defeating for Interlock Switches

From a safety standpoint, an interlock switch detects the open/close status of the door so that the machine can be run only when the door is closed. However, there are times when the interlock switch is defeated with and disabled so that the machine is left running with the door open, for example, because it is troublesome to open and close the door every time a workpiece is loaded or unloaded, or because the operator wants to perform adjustment work while the machine is running. This is an extremely hazardous situation where a serious accident could occur at any time.

To prevent this kind of defeating for the interlock switch, as shown in Figure 4, the interlock switch is designed so that it cannot be disabled by screws, needles, or plate metal pieces other than paired actuators, or common tools and objects such as keys, coins, and screwdrivers.