Safety components are used to provide safe control of machinery based on the concepts of machine safety for ensuring the safe operation and maintenance of machinery and equipment in factories, chemical plants, and other work sites. Sometimes safety components are built into machinery and equipment beforehand, and sometimes they are attached to the machinery and equipment as needed.

Safety components are useful for reducing the risks when using a machine.

If a safety component fails or is controlled differently than intended, the risk immediately increases and the possibility of harm to human is higher. For this reason, safety components are required to have specific safety functions (machine functions that could lead to increased risk if they fail).

Safety components used in machinery and equipment are used for the following purposes.

| Limiting the work envelope of machines Mechanical stoppers, wedges | Limiting the pressure of steam and air Release vents (safety valves) |

| Detecting the opening and closing of doors Interlock switches (Figure 1), safety limit switches | Preventing touching of machine moving parts Covers, lids |

Detecting the approaching of a person to the machine or | Quickly detecting contact by a person with the machine Bumper switches |

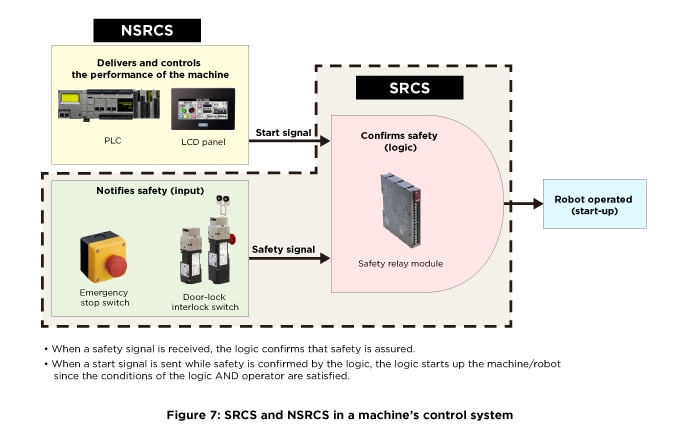

| Activating immediately when an operator senses danger Emergency stop switches (Figure 3) | Checking the safety status and allowing the machine to output Safety controllers (Figure 4), safety relay modules (Figure 5) |

| Ensuring safety during robot teaching and other operations Three-position enabling switches (Figure 6) |