LF3D Rugged Series

Excellent optical performance and robust construction suitable for use in machine tools

Key Features:

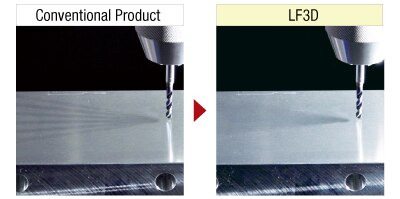

Eliminates the multi-shadow effect

Reduced multi-shadow effect enables easy visual inspection of the machined surface. [Patent pending (LF3D)]

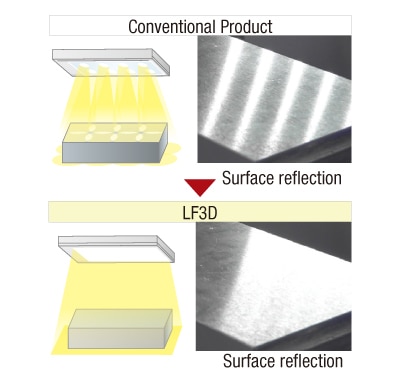

Reduces reflection from light source

LED light source reflects on the workpiece and stripes appear.

The LF3D LED allows the light to be evenly distributed

to provide natural lighting, and enables visual inspection.[Patent pending (LF3D)]

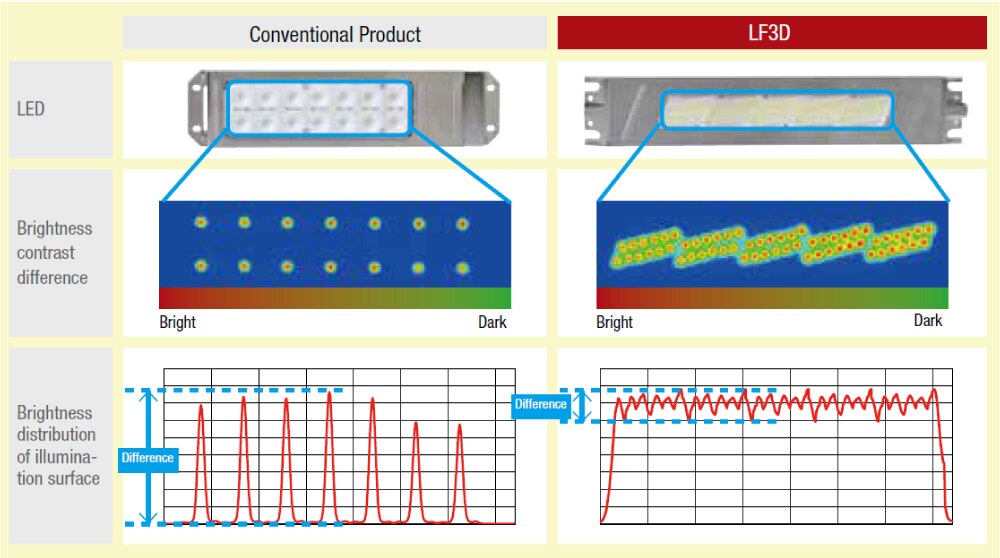

Uniform lighting provides uniform illumination inside the work area

By combining our optical design technology gained by development of LED lighting & sensors

and by optimum LED alignment, the brightness contrast difference is improved by 85%.

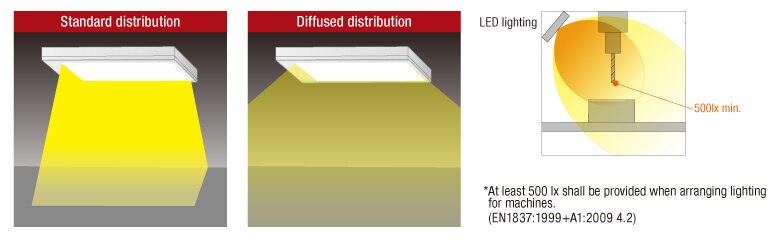

Select from standard or diffused light distribution depending on the machine tool needs

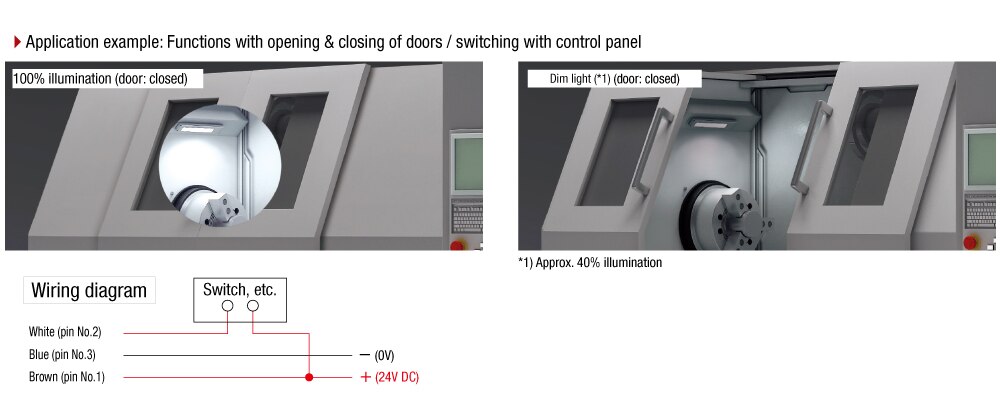

Equipped with glare mode to prevent operators from glare during maintenance [Patent pending (LF3D)]

Modes can be changed by just the wiring. Complicated settings such as PWM and dedicated controllers are not required.

Rugged construction and environmentally resistant

Suitable for use in machine tools

Degree of protection IP67G / IP69K

Oil-resistant gasket and unique structural design achieves IP67G protection degree. (*1)

Withstands exposure to water and oil. (*2)

IP69K for use in high-pressure, high-temperature washdown.

*1) IP67F (LF1D)

*2) Oil used for testing: Insoluble oil JIS N3-8

Robust material

Reinforced glass, stainless steel, zinc diecast, extruded aluminum prevents damage from scraps

Resistant to high temperature

Wide operating temperature range (up to 55℃).

Improved design and user-friendly

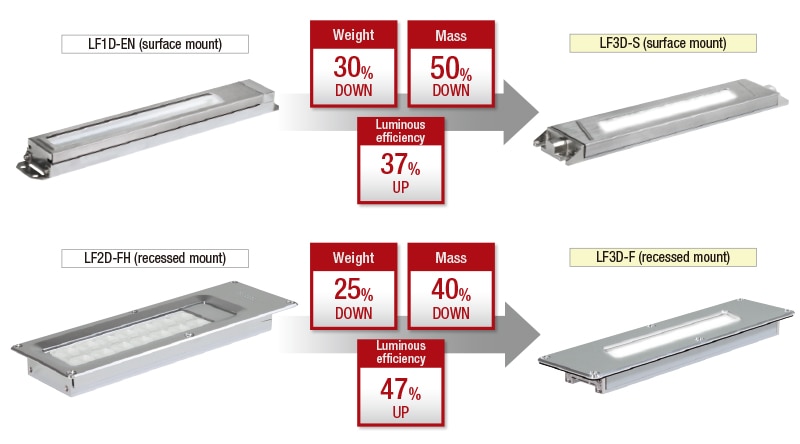

Compact, slim, and light compared to conventional products

Easy replacement with conventional products

Panel cut-out for older LED lighting will fit the new LF3D LED.

Accessories for surface mount type replacements available.

Wide variety of connector types available

Wide selection of models to suit a various machine tools

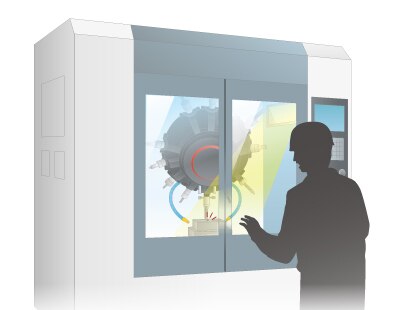

Effective solution for machine tools

LED lighting inside machine tool allows for clear identification of chatter marks

BEFORE

Hard to see chatter marks

Glares from LED lighting inside the machine tool could be mistaken as chatter marks while visually checking the machine operation. This often caused chatter marks to be left untreated, delaying maintenance and worsening the situation.

AFTER

LED lighting improves machining efficiency

IDEC's unique optical technology enables the light to shine evenly on the surface, suppressing multiple shadows and allowing the operator to

see scratches and unevenness on the workpiece. LF3D lighting makes it possible to check whether chatter marks have been generated or not easily, at a glance.